The REGULUS Eco Dryer is designed to reduce the plastic humidity content and to compact the waste.

What kind waste plastic can be used for Plastic Squeezer Dryer densifying Machine?

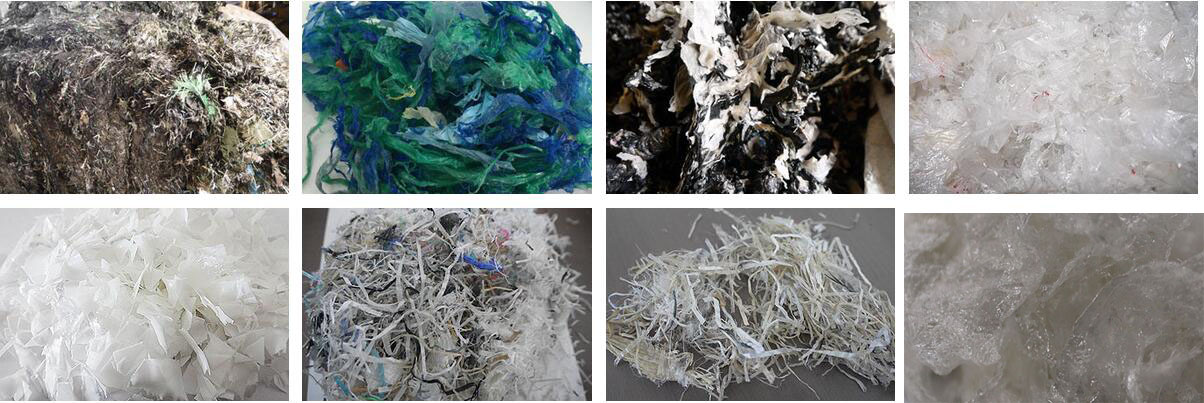

Recyclable waste: Plastic from washing line, Mixed plastics, LDPE HDPE PE PP Film, PE PP bags, raffia, jumbo bags, FIBC bag, RDF, Tetrapak Raw material photos: |

Reliable, versatile, the Squeezing Dryer removes the wet plastics water from 30 to 3% (in case of film material from washing lines), increases the apparent density of the material, even up to a factor of 10, and compacts the treated material. Increasing the density of material from 1 up to 10, compacting and drying from 30% down to 10% moisture. |

After the Plastic Squeezer Dryer densifying Machine, whatwill the plastic looks like?

What can we use the plastic for?

Through our squeezing dryer, washed materials can be squeezed to dehydrate water of films, bags flakes or fluffy stuff. The recycled materials become flakes or lumps . The moisture they contain will be lowered down to 3%. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. The quality and validity of the pellets and the efficiency of the extruder will be improved with the increased capacity.

|

Superior Features

| Always your best choice REGULUS Squeezer can help you SAVE cost,SAVE energy, SAVE time, PROTECT environment, and INCREASE productivity as well as efficiency. |

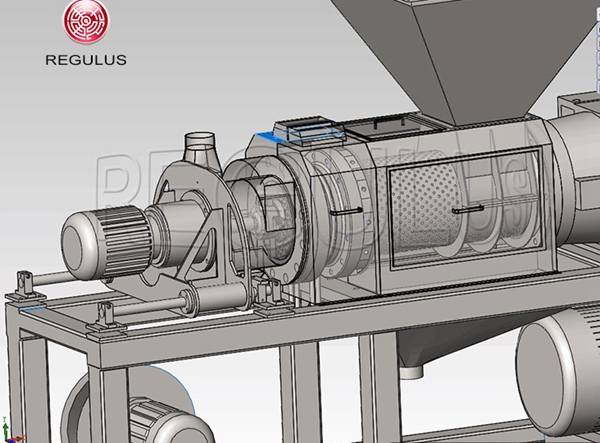

1 | The head part has water cooling and thermocouple temperature control device to ensure the temperature of the head and ensure the plasticizing effect. |

2 | The capacity and temperature can be adjusted within a certain range to meet the needs of different production environments. |

3 | Discharging conveyor matches with split centrifugal fan, greatly prolong the service life of fan. Wind pressure and wind can be adjusted to meet different conveying speed and conveying capacity. |

4 | Split type cylinder can be freely removed and replaced. Compared to the traditional integral machine cylinder, can reduce the user’s replacement and maintenance costs. |

5 | With overload automatic positive and reverse function, effectively avoid material blocking, material plasticizing and other problems. Electrical procedures and upper material delivery are fully linked, to ensure the stability of feeding and discharging. |

6 | Electrical control part all adopts well-known brand electrical components. controlling system takes PLC touch screen with button operation mode, all parameters can be set according to different working conditions and demand free, easy and simple to operate. |

Please select Your Model:

DS250 | DS300 | DS400 |

Main Motor: 55kw ~75kw Screw Diameter: 250mm

Product capacity: PE: 300kg/h ~ 350kg/h PP: 200kg/h ~ 250kg/h | Main Motor: 90kw ~110kw Screw Diameter: 300mm

Product capacity: PE: 500kg/h ~ 700kg/h PP: 400kg/h ~ 600kg/h | Main Motor: 160kw Screw Diameter: 400mm

Product capacity: PE: 900kg/h ~ 1000kg/h PP: 800kg/h ~ 900kg/h |

All of our products can be customizedaccording to customer requirements.

Video

DS Series DS300 for PP raffia