1. Introductionof Plastic Compacting pelletising machine

ThePelletizing system combines function of crushing, agglomerating, plasticizationand pelletizing all in a single step. The main of this system is single screwextruder with advance heat stabilization technologies resulting in high qualitypellets that helps to improve your final product line or sells good price tothe market.

ThePlastic recycling machinery and plant can be used for recycling plastic film,foam, raffia, scrap, bags, woven bags, ton bags and other plastic foamingmaterials re-pelletizing.

2. Technicalparameter of Plastic Compacting pelletising machine

Model | REGULUS-SFS | ||

Fit for | recycling plastic PP, PE, HDPE, LDPE, LLDPE, PA66, PC, PET, OPP, BOPP, CPP, BOPET, ABS, PBAT, PLA and etc. | ||

Final product | Plastic pellets, plastic granules | ||

Electric elements | Siemens, Schneider, ABB, Omron, etc | ||

Model | Screw diameter(mm) | L/D | Output(kg/h) |

SFS85 | 85 | 36 | 120-200 |

SFS100 | 100 | 36 | 200-400 |

SFS130 | 130 | 36 | 400-650 |

SFS160 | 160 | 36 | 600-800 |

SFS180 | 180 | 36 | 800-1200 |

CEcertification available.

Larger,more powerful models available based on your request.

3. Featuresof Plastic Compacting pelletizing recycling machine

Combinecrushing, compacting and pelletizing steps in one system, less labor cost.

Higherefficiency feeding, suitable for plastic film, filament, raffia, scraps,foaming materials.

Lowerinvestment cost for a high quality and durable machine.

Lowerenergy consumption with high production output.

4. Detailsof Plastic Compacting pelletising machine

| FEEDING MACHINE As standard design, the plastic scraps such as film, raffia, bags, filament, conveyed into compacting agglomerator room by feeding conveyor. For rolls material, the roll hauling device is an optional feeding method. The feeding machine motor drives of conveyor belt. Hauling device speed is adjusted by inverter. In case the metal material is feed into machine, we can install metal detector on the belt conveyor, and interlock feeder with electric control system. The metal detector can detect metal from raw material and sound the alarm, stop the feeder. |

| SHREDDING AND COMPACTING MACHINE There is the mechnical work of rotor knife and stator knife at the bottom of compactor. The blades will cut up feeding plastic. After continuos cutting and friction, the temperature of compactor and plastic material will gradually increase. Below the plastic material melting point, the material will be fed into extruder screw directly. Optimal designed guide structure compacts the material and directs it into extruder screw. This system enables a fast and stable feeding into the compactor directly into the extruder.

|

| SINGLE SCREW EXTRUDER Screw: By the screw’s rotation, the plastic material goes forward, to finish the processing of compacting, melting, homogenization. Material of screw adopts qualified nitride steel 38CrMoAIA, process of CNC, wirh nitride treatment, has the ability of corrosion resistance and wear-resisting. With the specialized design of screw, even running with high speed, the material of polyolefin can be well melted under lower temperature and lower melting pressure.

Barrel: Because of the super L/D ratio, the single screw extruder can be used as one stage or two stages extruder. Two stages extruders can be installed two steps screen filter. The double filter standard can improve the quality and performance of the final product particles. |

| MELT FILTRATION: The non-stop screen changer can be installed on head of extruder to present significant filtration performance. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

|

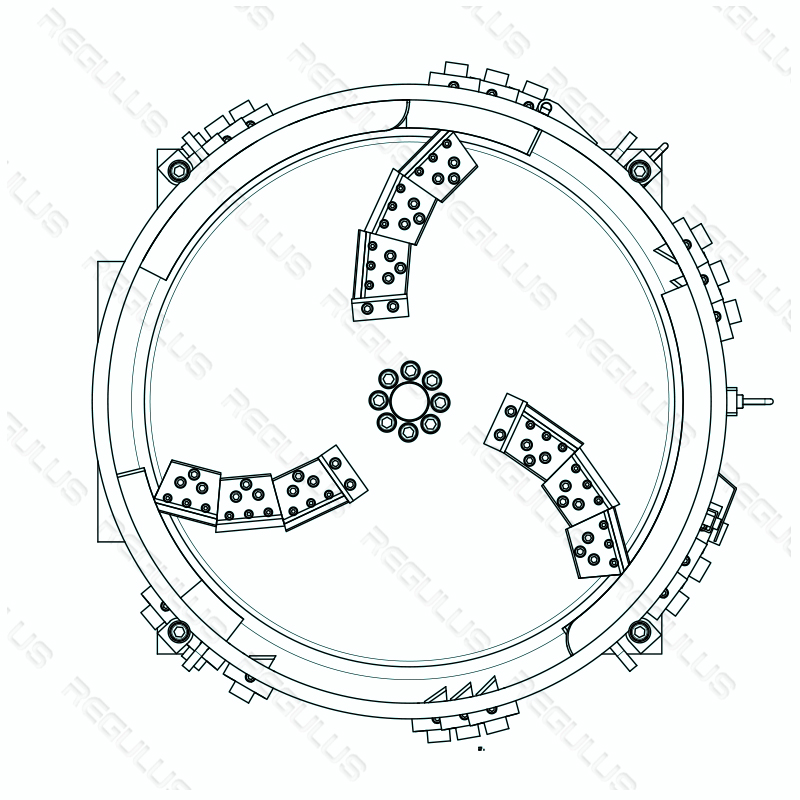

| PELLETIZING Die-face water ring pelletizing system as the standard granulating method. Self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure. Rotatory blades rotating speed is automatic adjusted base on melt extruding pressure. Our company also produces strand pelletizing system, which is suitable for High viscosity plastic. |

| CENTRFUGAL DEWATERING MACHINE This centrifugal drying machine is mainly used for the granules dewatering. The centrifuge force originated from the main shaft high speed rotating throws the granules and water together to the screen net, the water was separated through the screen net, while the granules stay inside the machine. Then the granules are sent to the next procedure. The bearing base adopts water-cooling structure, this design is good for the heat elimination and the decrease of the bearing’s temperature rise, and then the bearing can last longer. |

| VIBRATION The plastic particles are sent to the vibrating screen after drying, and the qualified plastic particles are left on the screen surface, and then sent to the storage bin through a fan. The unqualified plastic particles pass through the sieve holes and are transferred to the lower layer or the conveyor. In this way, the size of the plastic particles is layered and the screening process is completed. The vibration machine can ensure that the final particle quality is perfect. |

| PLASTIC GRANULES Final output: plastic particles, plastic pellets |

5. Delivery,shipping and serving

Delivery:The regular machine delivery time of REGULUS plastic recycling machine is 45working days.

Shipping:The machine could be sent by ship(LCL or whole containers), train, truck.

Allthe machine are tested before delivery.

Overseasinstallation and training are avaiable.

24hours online Questions & Answers

Machinespare parts in stocking and in-time delivery.

6. FAQ of Plastic Compacting pelletizingrecycling machine

Question1: What kind plastic can your plastic recycling machine recycle?

Answer1: We have different plastic recycling machine, mainly for recycling PE, LDPE,LLDPE, HDPE, PP film, bags, bottles, rigid injection plastic. And PET bottles.

Question2: What model do you have for plastic recycling machine?

Answer2: We can produce different model, from 300kg/h to 2000kg/h for plasticcrushing washing drying line. And 100-1000kg/h for pelletizing recyclingmachine.

Q: Can you make different solutions according to different wasteplastic?

A: Yes, we can make different design according to customer’srequirement.

7. Video of the plastic pelletising system