PLC Control System Automatic Plastic PE Film Granulator Machinery Agglomerator

PLC Control System Agglomerator Machine

Agglomerator machine can directly make material into granules.

The agglomeration machine can be used for a wide range of raw materials,such as plastic PE film, HDPE

foil, LDPE film,PE bags,PP woven bags,PP non-woven,PP raffia,plastic sheet,flakes,fiber,PS,EPS and other

soft plastics.

Application:

plastic PE film HDPE foil PP woven bags LDPE film

Why Choose Densifying Machine with PLC Control System?

The automatic agglomerator machine is different from ordinary agglomerator machine. It has a belt conveyor for

feeding, a screw feeder for discharging, and is equipped with an automatic control PLC touch screen electrical

cabinet.

Belt conveyor feeding | The automatic agglomerator machine uses a belt conveyor for feeding, which means that the raw materials can be transported to the processing area more evenly, improving production efficiency and processing quality. |

Screw feeder discharging | Compared with ordinary agglomerator, the discharging end of the automatic agglomerator uses a screw feeder. This design can ensure uniform discharging of the product and reduce possible problems during discharging, clogging or unevenness. |

PLC control system | PLC control means that the production process can be more accurately controlled and monitored. |

PLC touch screen electrical cabinet

Specification:

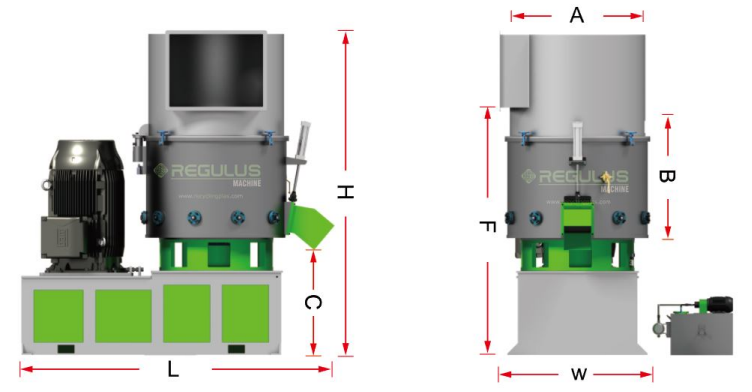

Model | 500L | 600L | 800L | 1000L | 1500L |

Dimension L*W*H(mm) | 2400*1060*2740 | 2400*1060*2800 | 2500*1300*2800 | 2600*1400*2880 | 2750*1500*3040 |

Main Shaft Speed(r/min) | 850 | 750 | 650 | 650 | 650 |

Main Motor Power(KW) | 75 | 110 | 132 | 160 | 250 |

| Weight(kg) | 3650 | 4000 | 4650 | 5130 | 5700 |

Main Parts:

Features:

| Stable and reliable | a)The spindle has undergone good heat treatment and finishing b)The inner surface of the pot body and pot bottom is finely polished c) It adopts high-performance mechanical components and structural design d) advanced electric motors and transmission systems with low power and high efficiency high output. |

| High degree of automation: | a) PLC control on the electric cabinet, when the agglomerate inside material is full, the belt conveyor can stop to feed material automatically. b) The machine can spray water automatically, and discharge material automatically. |

| Easy to use and maintain | The blade may use demountable blade. So it is much convenient to repair and use |