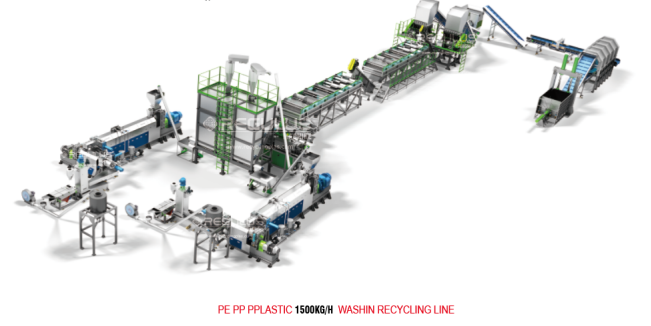

PE Film/ PP Woven Ton Bag Wahing Recycling Line (500-1500kg/h)

Brief introduction:

The whole washing line equipment is researched, design and manufactured by our company,

integration of Europe technology, it has features as high efficiency, working stable, low humidity content(less than 5%).

We use good quality on our washing machine(SUS-304,more than 3mm thickness)

ensures whole production equipment long service life time.

Product highlights

🔹 Efficient washing:

Multi-stage washing process: adoptsmulti-stage processes such as pre-washing, friction washing,

floating washing,etc. to effectively remove various impurities such as oil, mud, glue, etc.

🔹 Intelligent control:

Fully automated operation: intelligentcontrol system, easy operation, one-button start, reducing manual intervention.

🔹 Durable:

High-quality materials: stainless steel andwear-resistant materials are used. Ensure that the equipment

iscorrosion-resistant, wear-resistant and extend its service life.

Easy maintenance design: modular design,easy disassembly and maintenance, reducing downtime.

Applications:

This washing line can be suitable for recycling waste soft plastic PE HDPE LDPE LLDPE film, bags,

foil, PP ton bags, woven bags.

post-industrial plastics pp woven bag

Product Capacity:

300kg/h to 1000kg/h.

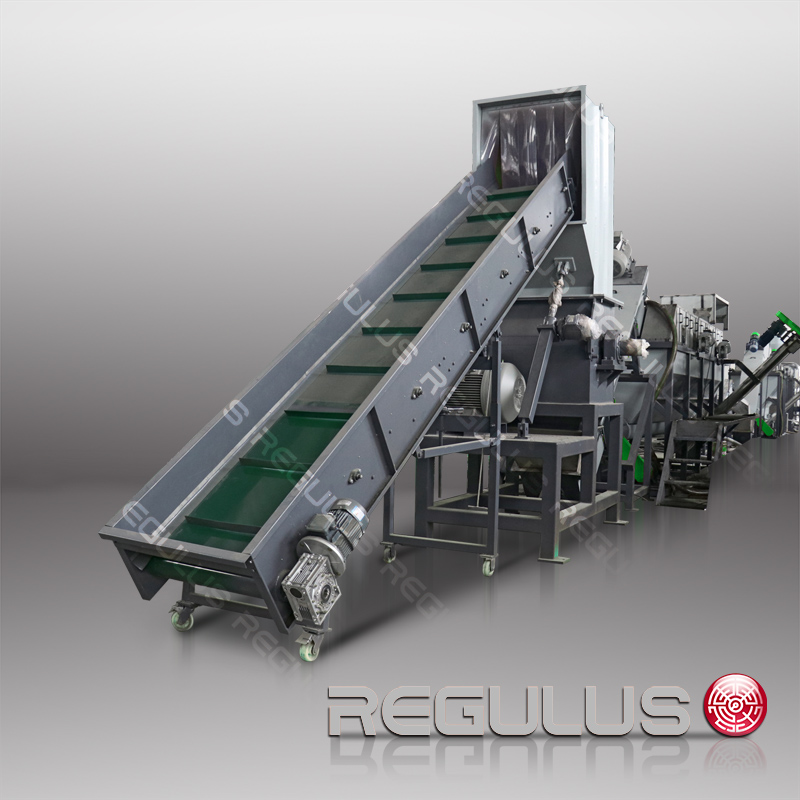

Working flow:

Belt conveyor→crusher→friction washer→Floating washer→Screw feeder→

Dewatering machine→Hot air drying system→Storage hopper→Control cabinet

Specification:

| Model | PE-R500 | PE-R1000 | PE-R1500 |

| Dimension(㎡) | 350 | 700 | 1000 |

| Installed power (kw) | 500 | 800 | 1300 |

| (PE) Productivity(kg/h) | 500 | 1000 | 1500 |

| Water consumption(m³/h) | 3 | 5 | 7 |

Function of main equipment:

a.Belt conveyor:conveying or transporting dirty plastic films into crusher.

If too much scrap iron,metal detector may be needed.

b.Plastic crusher:cutting or shearing type:cutting jumbo film or bag into small pieces

c.High speed friction washer:clean the dirty on the surface of film scraps

d.Floating washer: clean the rest dirty on the surface of film scraps

e.Dewatering machine:dewater for film scraps to get final good quality film scraps

f.Hot air drying system and air blower: use hot air to remove the moisture from PP/PE scraps.

g.Storage hopper:store the PP/PE scraps for next step packing.

Video: