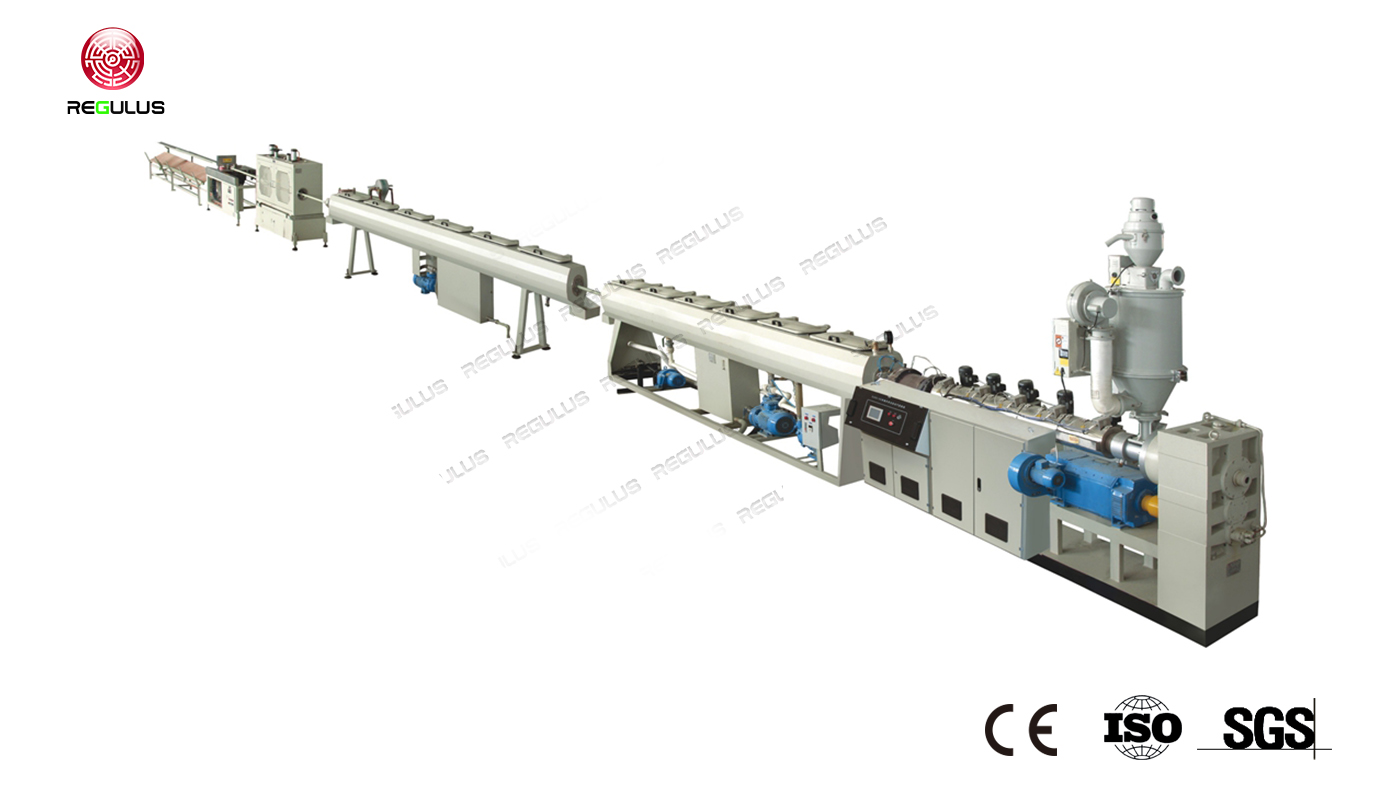

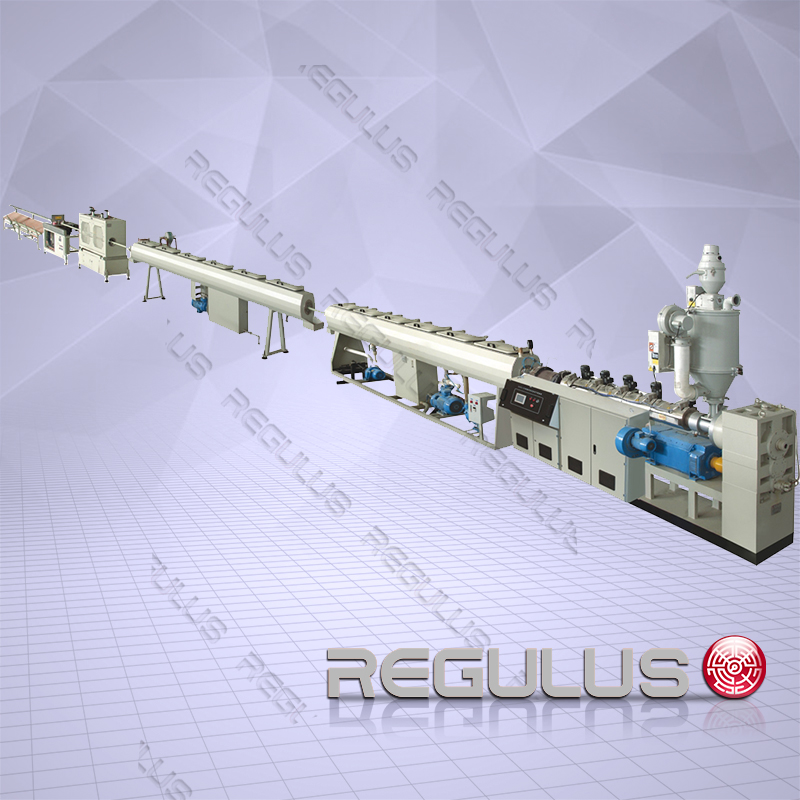

The line is used for extrusion of PP-R,REX or PE-RT pipes.PP-R pipe are non-toxic,heat-resistant,It can beeasily welded by hot-melting method and recycleable.PEX pipes does not need the cross-link process,and it also be recycled.This line is assembled lattice or spiral mould.Two section vacuum calibration unit and spraying cooling bath.After simply changing the mould,it also becomes possible to produce ABS,PP composite pipe.

Flow chart of extruder plastic machine:

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder→ color band extruder → mould and calibrator → vacuum calibration machine → cooling tank→ haul-off machine → cutting machine → stacker(Winding machine)

The extrusion line consists of several components and processes that work together to produce PPR pipes of various sizes and specifications. Here is a brief overview of the typical components and their functions:

1. Raw Material Handling:

The PPR extrusion process begins with the handling of raw materials. PPR resin, along with additives like stabilizers,antioxidants, and colorants, is fed into the extrusion line.

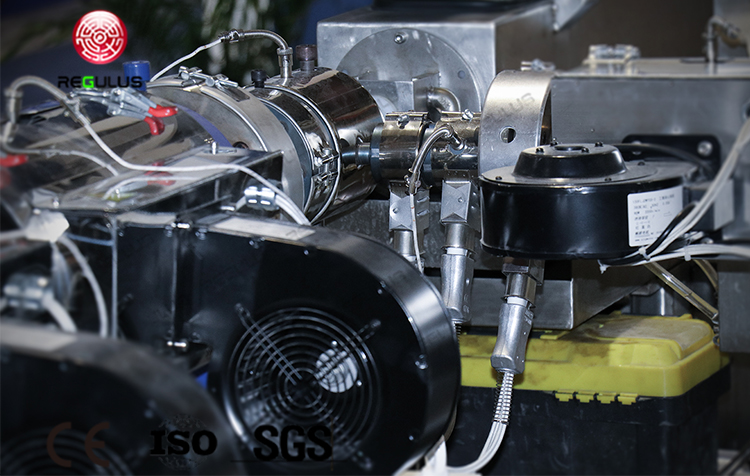

2. Extruder:

The extruder is a key component of the extrusion line. It melts and homogenizes the PPR resin and additives,forming a consistent melt. The extruder consists of a barrel, where the material is heated and mixed,and a screw, which conveys the molten material forward.

3. Die Head:

The die head is responsible for shaping the molten PPR material into a pipe. It has an opening orifice that defines the outer diameter of the pipe and may include additional features like co-extrusion layers or markings.

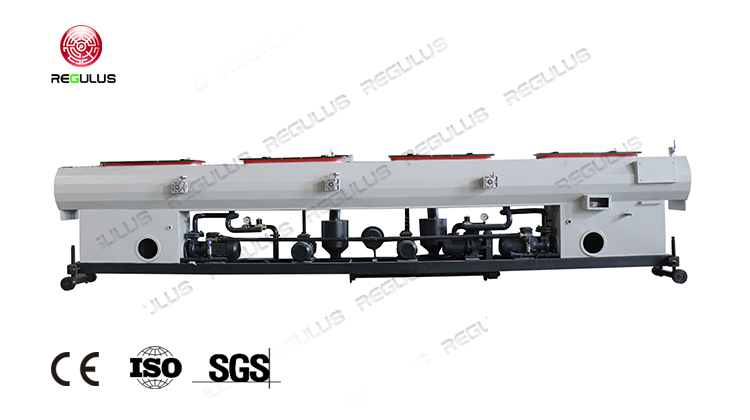

4. Vacuum Sizing Tank:

After exiting the die head, the molten PPR material enters a vacuum sizing tank. The tank is filled with water, and its purpose is to cool and solidify the material while maintaining the desired shape and dimensions. Vacuum is applied to ensure uniform cooling and prevent deformations.

5. Haul-off Unit:

The haul-off unit consists of caterpillar-type traction belts that grip the solidified pipe and pull it through the extrusion line at a controlled speed. This process helps to maintain the dimensional accuracy of the pipe and provides tension for subsequent stages.

6. Cutting Unit:

Once the pipe has been pulled through the extrusion line, it is cut into the desired lengths. Different cutting mechanisms can be employed, such as a saw, guillotine cutter, or planetary cutter, depending on the required precision and production speed.

Overall, the PPR pipe extrusion line is a complex and automated system that combines different processes to produce high-quality PPR pipes. The line can be customized to meet specific production requirements, such as pipe diameter, wall thickness, and output capacity.

| Pipe range (mm) | 16-63 | 20-110 | 75-160 | 90-250 | 110-315 | 160-450 | 315-630 |

| Extruder | 65/30 | 65/33 | 75/30 | 75/33 | 90/33 | 90/33 | 120/33 |

| Motor power(kw) | 30/37 | 55/75 | 75/90 | 90/110 | 132 | 160 | 280 |

| Capacity(kg/h) | 100-150 | 200-300 | 200-300 | 220-350 | 300-400 | 350-450 | 600-600 |

| Max.speed | 15m/min | 10m/min | 8m/min | 6m/min | 3m/min | 1.2m/min | 1.0m/min |

We are manufacturer.

2. How about the price?

You know ,the goods counts the the price. We select the best machine raw material such as siemens electrics,schneider and ABB etc.We will provide you the best machine with best price.

3. What price terms you offer?

FOB, CIF, EXW and other price terms based on your kind request.

4. How about the machine quality?

Our machine quality is reliable. We select every parts on the machine strictly and production and installation is done by professional workers. We test the each production step for the best machine.

5. What kind machines we produce?

Our factory produce plastic pipes machines, plastic recycling machine.

6.How can we check the machines before delivery?

We can provide online checking when testing the machine on site. We will take and prepare detailed testing videos for your checking before the delivery. We accept third-party testing. Except above points, we will provide detailed testing report.

7. How long is your machine's guarantee time?

One year.

plastic machines, our main products include:Plastic PE PP PET PVC PS PA plastic crushing, washing, drying recycling line

Plastic PE PP PET PVC PS PA pelletizing/Granulating recycling line

Plastic shredder, Plastic crusher, Plastic agglomerator, Plastic mixer, Plastic pulverizer equipments

Plastic pipe extrusion production lines

PVC/ WPC profile extrusion line

Please feel free to contact us for further details.

We are looking forward to forming a profitable business relationship with your company in the near future.

And Welcome to China, welcome you to visit our company at any time.