What kind of plastic film can be recycled?

The plastic film is a secondary resource with very good recycling value, and the recycled film can reproduce film products,

plastic bags, injection products, wood plastic products, etc., and has a wide range of uses.

The shape, size, moisture content, and impurity content of the waste film are not the same.

The types of plastic films commonly found in the recycling market are:

1. Production of post-consumer films(including collected from landfills and selectively collected)

2. Commercial and post-industrial films(mainly in plastic bags and packaging films, stretch film)

3. Agricultural film (including greenhouse,mulch, greenhouse film and banana film, etc.)

Mainly in Plastic PE, PP, LLDPE, HDPE,LDPE.

Recycling solution for waste plastic film

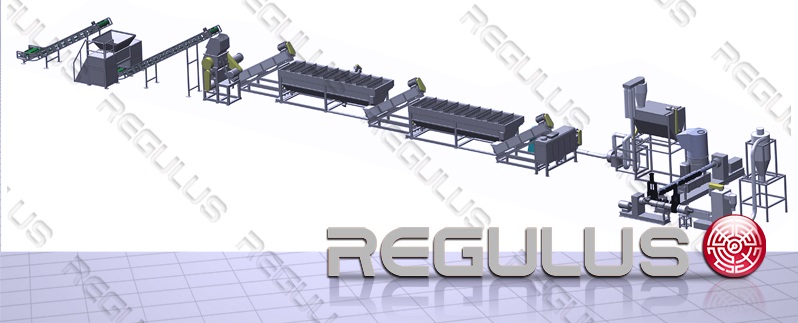

We REGULUS machinery company offer one of the most robust and effective turnkey solutions for plastic film recycling .

Whether you're working with polypropylene (PP), polyethylene (PE), orother plastic films, our complete plastic film

washing line will fulfill your every need for recycling loose or baled plastic film into plastic pellets. And you can sell

the plastic pellets for good marginss.

This fully automated plastic film washing and second step pelletizing line is composed of a series of plastic

recycling machines in a specific order optimized for efficiency . Our standard washing lines are available

with the input capacity of 300kg/hour up to 2000kg/h.

While our standard PE film washing line sare sufficient for most recycling plants, custom setups with

additional machinery and increased capacity can be designed for your specific needs.

Main Technical parameter for Plastic film washing lines

Model | Product capacity | Motor power | Equipment footprint |

PEW-300 | 300 kg/h | 100 kw | 120 m2 |

PEW-500 | 500 kg/h | 150 kw | 200 m2 |

PEW-1000 | 1000 kg/h | 190 kw | 310 m2 |

PEW-1500 | 1500 kg/h | 250 kw | 500 m2 |

PEW-2000 | 2000 kg/h | 290 kw | 600 m2 |

▲ CE certification available.

▲ Larger, more powerful models available based on your request.

Main equipments of Plastic film recycling line

The entire plastic film washing line is controlled via a central electric control panel and cabinet.

Plastic Shredder Machine:

As long pieces of plastic film easily tangle and clogs conveyors and rotary-based machines, the first step is to cut

the plastic film into smaller pieces using a plastic shredder machine. The shredder is usally equipped for

large capacity washing line, and the shredder can shred whole film bales directly.

Wet Plastic Granulator:

The plastic granulator cuts the plastic film into smaller pieces. With water constantly injected into the cutting chamber,

our wet granulation process also "pre-treats”and partially cleans the plastic film before moving onto the next

washing machine.

Friction Washer:

The friction washer is high rotating speed cleaning equipment. The rotating speed is around 1000rpm.

When the plastic film crushing pieces enters the friction washer, the plastic film runs against each other

at high speed geeting rid of hard to remove contamination.

At the same time, any paper and cardboard is broken down into fibers and removed .

While one friction washer is standard,various washing plants have requested a secondary friction washer

to ensure thorough cleanliness. We can custom-made different washing line design according to different waste film.

Sink Float Separation Tank:

Using water as a medium , materials thatfloat are separated from materials that sink . In the washing tank,

the plastic PP and PE films will float, and heavier contamination such as dirt, sand, glass, metals, and other plastics will sink .

A screw conveyor at the bottom of the sink float separation tank removes the contamination.

While separation is one aspect of this apparatus, a secondary function is to further clean the plastic film.

Centrifugal Dewatering Machine:

The first step in the drying process , our centrifugal dewatering machine uses centrifugal force to remove a large portion

of water within the plastic film before moving forward onto the therma dryers. As thermal dryers use heat to

dehydrate water, it requires more energy consumption during operation . The use of the dewatering machine is

beneficial in savings for long run operations costs.

Thermal Dryer + Cyclone Separator:

The clean plastic film is vacuumed out ofthe dewatering machine and into the thermal dryer system where the plastic film

will travel down a series of stainless steel tubes mixing with hot air . There maining moisture is dehydrated in this process

which ends with a cyclone separator . The cyclone separator allows the plastic film to mix with a freshstream of cold air

which prepares it for storage into the product silo. The cyclone separator is also effective in removing fines and dust.

Screw Press Squeezing dryer and agglomerating Machine:

An optional piece of equipment , the screw-press dewatering and agglomerating machine is a more advance version

of the standard dewatering machine . Instead of using centrifugal force to remove water from the plastic film,

the screw press squeezes the water out via high pressure . This machine can actually take the place of both

the dewatering machine and thermal dryers and agglomerator.

Plastic Pelletizing Machine:

After washing line, the next recycling stepis plastic pelletizing line.

The clean film needs to be processed into plastic pellets before it can be used in production.

To do so, we offer different model of plastic extruder pelletizing line. The pelletizier has

die-face water-ring pelletizer and strand type pelletizer.

Machine running video reference 2: