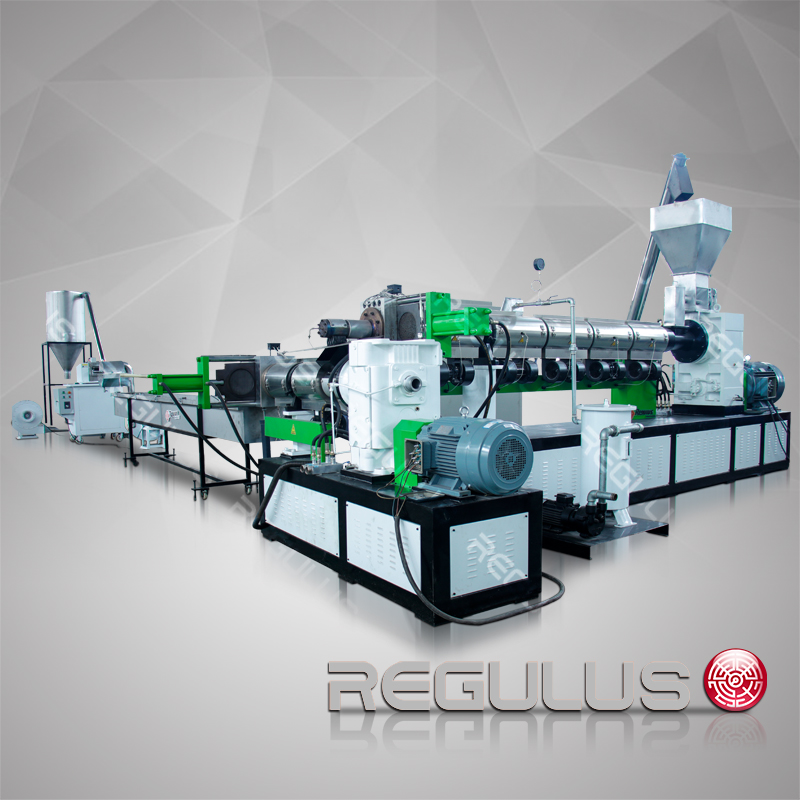

Rigid Plastics Granulating Line

Features:

1. Plastic granulation recycling machine line with high output and excellent granulating ability

2. Simple structure, easy operation, large capacity, energy-saving, safety, eco-friendly way

3. Automatic controlling, compacted structure, excellent production ability, perfect granulating ability

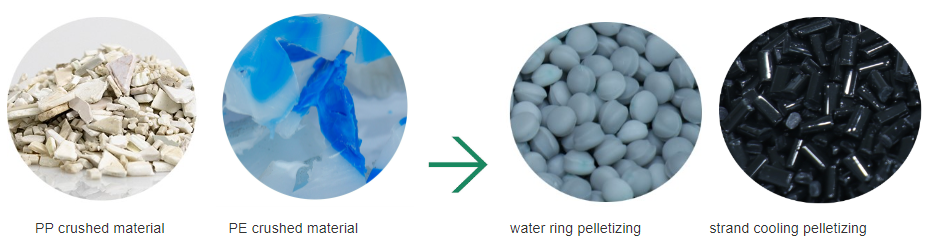

Applicable Materials:

HDPE, LDPE, LLDPE, PP, PE, PET, PA, BOPP, PS, PC, HIPS, ABS,PMMA, TPU, EVA and other waste

rigid plastic material.

Specification:

From 100kg/h to 1000kg/h. Please select Your Model.

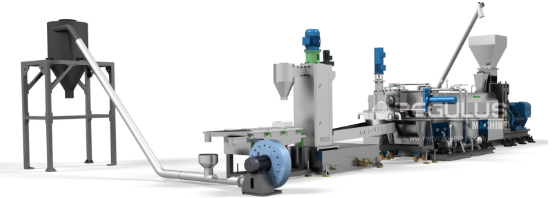

Single Stage granulating line:

Single Stage Granulating Line (Water Ring/ Die Face Cutting Pelletizing)

Single Stage Granulating Line (Strand Cooling/Spaghetti Cutting Pelletizing)

| Model | SJ-90 | SJ-100 | SJ-120 | SJ-130 | SJ-160 | SJ-180 |

| Extruder power(kw) | 55 | 75 | 110 | 132 | 185 | 250 |

| Screw diameter(mm) | 90 | 100 | 100 | 130 | 160 | 180 |

| (PE) Productivity(kg/h) | 100-200 | 200-300 | 250-400 | 450-550 | 550-850 | 800-1000 |

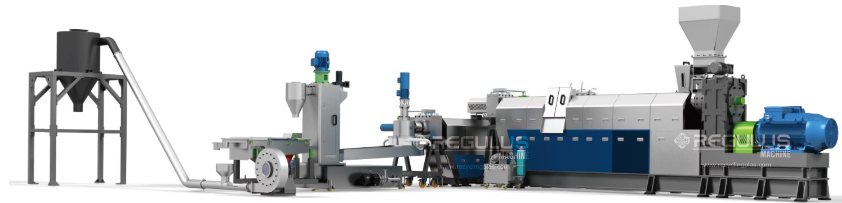

Double stage granulation line:

Two Stage Granulating Line (Strand Cooling/ Spaghetti Cutting Pelletizing)

Two Stage Granulating Line (Water Ring/ Die Face Cutting Pelletizing)

| Model | SJ-90 | SJ-100 | SJ-120 | SJ-130 | SJ-160 | SJ-180 |

| Extruder power(kw) | 55+22 | 75+30 | 110+37 | 132+45 | 185+55 | 250+75 |

| Screw diameter(mm) | 90+100 | 100+100 | 100+100 | 130+130 | 160+180 | 180+200 |

| (PE) Productivity(kg/h) | 100-200 | 200-300 | 250-400 | 450-550 | 550-850 | 800-1000 |

Strand pelletizing:

Mainly used for high viscosity materials.

Individually extruded strands will be cooled down in a water cooling tank and then be cut by a pellet cutter.

※All of our products can be customized according to customer requirements.

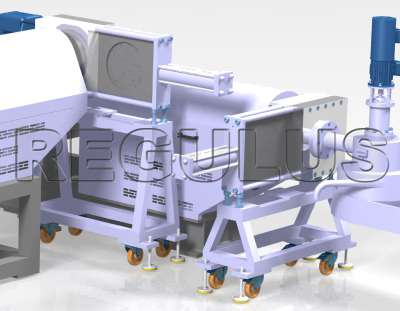

Structure of Rigid Plastic Recycling Granualting Machine:

The SJ series single screw plastic regrind pelletizing system combines quantitative feeding,

high efficiency extruder, different type of filter and different typesof pelletizer by modular design.

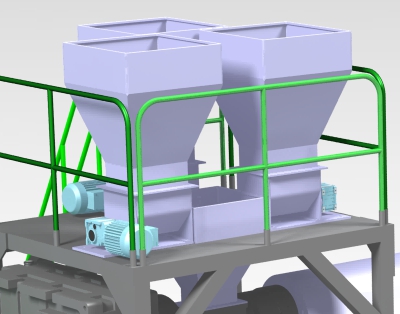

Feeder

Dosing feeder with inverter controller which ensures the extruder run steadily.

Extrusion

High efficiency barrel and screw used for extruder with excellent plasticizing result and high output capacity.Adopt high wear resistant alloy material to ensure 1.5 times service life of normal one.

Degassing

Force vacuum degassing system to get rid of the low molecular, moisture and printing ink effectively,make sure high quality output pellets.

Filter

Plate type, piston type, back flush type and automatic self-cleaning type filter,you have different choice according to impurity contents in material and your habit.

Pelletizer

Vertical and horizontal water ring pelletizer, Cutting speed of pelletizer controlled automatically by inverteraccording to the pressure of die head, which could achieve the uniform size for output pellets.

Pellets Drying

Centrifugal dryer is mainly used for drying granules. The centrifuge force originated from the main shafthigh speed rotating throws the granules and water together to the screen net,

the water was separated through the screen net, while the granules stayinside the machine.

Then the granules are sent to the next procedure.

REGULUS company makes plastics recycling extremely efficient and profitable over the long term.

Highest productivity and flexibility, low energy consumption, easiest operation.

That is what makes our plastics recycling machines stand out.

Our plants are designed for high-quality pellets. So that they can produce first-class products at a later stage.