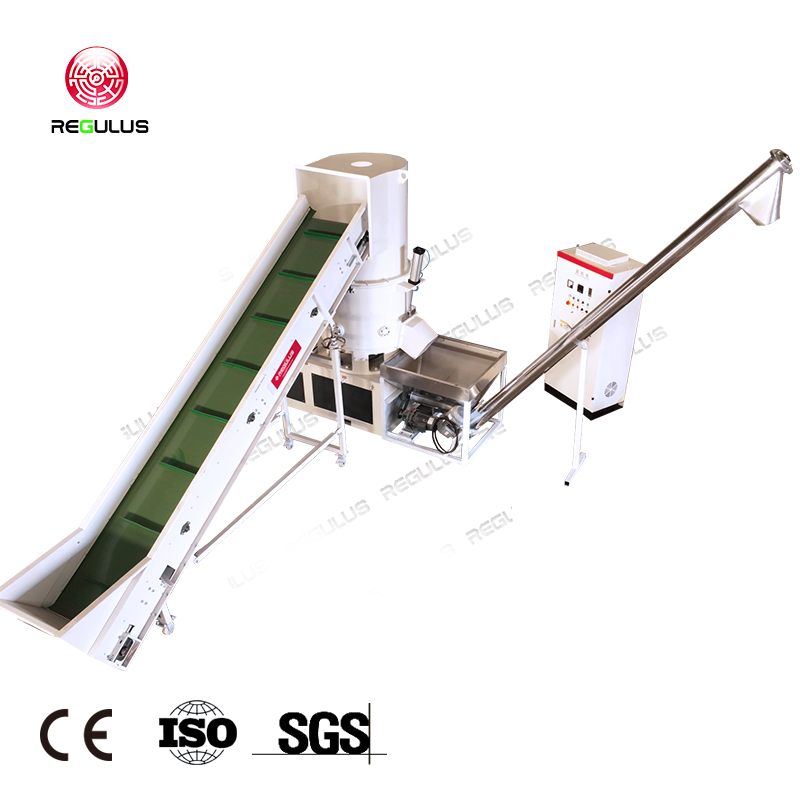

Plastic agglomerator is a kind of high-efficiency recycling equipment specially used for processing waste plastics,

which is widely used in the plastic recycling industry. By heating and densifying the waste plastics, the agglomerator

processes them into granules that are easy to store, transport and reprocess.

♻️Efficient production

The agglomerator can directly process plastic into pellets through rapid heating and granulation process, which is

suitable for subsequent production, greatly shortening the processing cycle and improving production efficiency.

♻️Strong applicability

It is suitable for a variety of plastic waste, including PE film, PP woven bags, hard plastics, foam plastics, etc. It

has extremely high versatility and can meet different recycling needs.

♻️Easy maintenance

The equipment structure is reasonably designed, and the key components are made of wear-resistant materials,

with a long service life, convenient daily maintenance, reduced downtime, and improved production continuity.

♻️Improve feeding efficiency

The belt conveyor realizes continuous and uniform material transportation, avoiding the uneven problem

caused by manual feeding.

Reduces the frequency and labor intensity of manual operation, while reducing the risk of equipment

downtime or damage caused by human errors.

Can easily handle large quantities of materials, especially suitable for large-scale production scenarios.

♻️Optimize discharging efficiency

The automatic discharging function quickly delivers the processed finished products to the designated

location without manual intervention, saving

labor costs.

Avoids material scattering or contamination that may be caused by manual handling, improving the

quality of finished products and production efficiency.

Supports linkage with other production equipment to achieve full process automation and

significantly improve enterprise production capacity.

Video: