Post-consumer PET Bottles Washing and Recycling Line(500-3000kg/h)

PET bottle flake washing line is a series of equipment used to clean and process post-consumer

PET bottles into clean, recyclable PET bottle flakes.

The end result of the cleaning line is high-quality, clean PET flakes that can be used to manufacture

a variety of products such as textiles, packaging materials, etc. The flakes get from this line can be used for producing 2-D or 3-D PSF, straps, sheet and etc

.

Remark:

We will make different PET recycling line design according to different raw material.

What is plastic PET?

PET is among those plastics which are an important part of your everyday life.

It is an important commercial polymerhaving application ranging from packaging,

fabrics, films to molded parts forautomotive, electronics and many more. You can

find this famous clear plastic around you as water bottle or soda bottle container.

Why Use PET Washing Line?

a.PET waste bottles are dirty and must undergo strict washing before granulation to remove oil,

dust and other sundries.

b.In addition, Waste PET bottles often come with caps, labels, bases and other accessories

whose materials are incompatible with PET. Therefore, in the recycling and pelletizing process

of waste PET bottles, these accessories must be sorted out separately.

Application:

PET Bottle/Flakes Washing Line applies to waste PET plastic recycling with different pollution levels.

The recycling line is suitable for recycling ABS, PVC.

Recycled PET is in good value and has a wide range of application: to produce PET strapping, PET sheets,

fibers, etc.

Working Flow

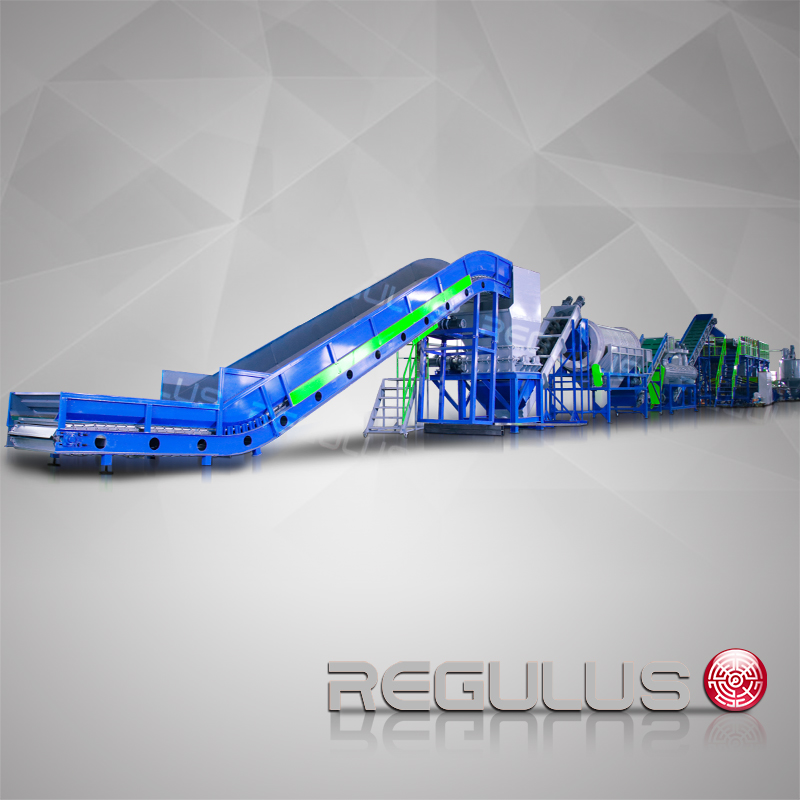

Debaler machine→Pre-washer→Label Remover→Sorting platform→Crusher→Washer Tank→Friction washer→Hot washer→

Friction washer→Waher Tank→Dehydration→Dryer→label separation→Color sorting→Bagging

This PET bottle recycling machine is consist of the following machines: Bales opener, Pre-washer,

label remover, manual sorting table, metal detector, crusher, hot washer, floating tank, drier, label blower,

hopper and electric cabinet.

| Pre-Processing Part | Pre-processing modular is freely consists of bale breaker, pre-washer,metal detector,label remover, and some other equipments. It provides pre-treatment for the raw material. |

| Size Reduction Part | Large materials are processed into small pieces, which improves the washing result and makes the final product easy to packing |

| Washing Part | Dust, glue, label, oil and other impurities can be removed highly effective by washing. This part combines foating washer, hot washer, friction washer. |

| Drying Part | Drying treatment is used to remove the moisture in the material with low packing density. |

| Sorting Part | Many other technology is used to separate material and color to purify and sort products. |

PET Bottle 2000kg/h Washing Recycling Line

Specification:

| MODEL | PET-500 | PET-1000 | PET-2000 | PET-3000 |

| Dimension(m²) | 350 | 700 | 1000 | 1500 |

| Installed power (KW) | 180 | 288 | 380 | 380 |

| (PE) Productivity (kg/h) | 500 | 1000 | 2000 | 2000 |

| Water consumption (m³/h) | 2 | 4 | 6 | 8 |

Our Regulus company can provide our customers with proper technical solutions

and state-of-the art recycling technologies.

Delivering a response tailored to the frequently changing needs of its customers

and of the market.

▲ CE certification available.

▲ Larger, more powerful models available basedon your request.

What equipment does the PET bottle washing line include?

Main equipment of PET Washing and RecyclingLine:

Bales opener/bale breaker: The bale breaker is driven by motors with slow rotation speeds. The shafts are provided with paddles that break the bales and allow the bottles to fall without breaking. |

|

Dry separation/ Trommel: This machine allows the removal of many of the solid contaminants (sand, stones, etc.), and represents the first dry cleaning step of the process. It is an optional piece of equipment, the trommel is a slowing rotating tunnel lined with small holes. The holes are slightly smaller than the PET bottles, so small pieces of contamination(such as glass, metals, sand, stones, etc.) can fall through while the PET bottles move onto the next machine | |

Label remover/ Delabeler: REGULUS has designed and developed a system that can easily open the sleeve labels without breaking the bottles and saving most of the bottles necks. The bottle material is input from the feeding port by the conveyor belt. When the blade welded on the main shaft has a certain included angle and spiral line with the center line of the main shaft, the bottle material will be transported to the discharge end, and the claw on the blade will peel off the label | |

Plastic granulator/wet grinding: Through the granulator, PET bottles are cut into smaller pieces to achieve the required size distribution for the washing sections that follow. Normally, crushing flakes size between 10-15mm. At the same time, with water constantly spraying into the cutting chamber, a first washing process is performed in this section, eliminating the worst contaminants and preventing them from entering the downstream washing steps. | |

Washer tank/ Sink and float separation: The target of this section is to remove any polyolefins (polypropylene and polyethylene labels and closures) and other floating material and to conduct a secondary washing of the flakes. The heavier PET material will sink to the bottom of the flotation tank, from where it is removed. A screw conveyor at the bottom of the sink float separation tank moves the PET plastic to the next piece of equipment. | |

Hot Washer System: Hot washed PET flakes are of higher value because this process dissolves glues(used to glue labels onto the bottles) and leftover beverages/foods that are difficult to remove in a cold wash process. Although you can just use water in the hot washer system, adding washing agents can added for better results | |

Dryer: Centrifugal dewatering machine: Initial mechanical drying through a centrifuge allows the removal of water deriving from the final rinsing process.

Thermal dryer: The PET flakes are vacuumed out of the dewatering machine into thermal dryer, where it travels down a series of stainless steel tubes mixed with hot air. So the thermal dryer properly treats the flakes with time and temperature to remove surface moisture. | |

Fines separation/Dust remover: It is an elutriation system, which is used to separate remaining labels, having dimensions close to those of the PET flakes size, as well as PVC, PET film, dust and fines. | |

Product silo: A stotage tank for the clean and dry PET flakes. |

|

PET flakes pelletizing machine: For the most part, PET flakes are used to produce using product directly. There are also some customers requiring plastic pelletizing machines. For more information see our plastic pelletizing line. | |